The Material Handling Institute (MHI) is the nation’s largest material handling, logistics and supply chain association. In their 2015 MHI Annual Industry Report prepared with Deloitte, they highlighted several Supply Chain Innovations that they indicate are key to helping supply chains meet the demands to be better, faster and cheaper. One of the top eight […]

Month: March 2015

Make Your Data Work Harder So You Can Work Smarter

Check out this video from the new Zebra Technologies. “We live in a connected world, and technology is embedded in everything we do. Converting the physical to the digital allows you to know the location, motion and state of your assets, people and transactions. Harnessing this new wave of technology empowers businesses with Enterprise Asset […]

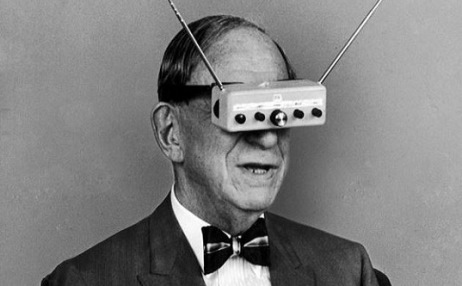

Technology, Watches, and Wearables Oh My

With the #AppleWatch event only minutes away, the internet is a buzz about wearables and the next big thing. ‘Wearables’ refers to the electronic technologies or computers incorporated into watches, contact lenses, eyewear, bracelets, rings, clothing and more — all designed to be worn on the body. Wearables can be anything from wristwatches that discreetly alert […]

What is the Internet of Things (IoT)?

By definition from Wikipedia The Internet of Things (IoT) is the network of physical objects or “things” embedded with electronics, software, sensors and connectivity to enable it to achieve greater value and service by exchanging data with the manufacturer, operator and/or other connected devices. Each thing is uniquely identifiable through its embedded computing system but is able […]